HACCP is the abbreviation for «Hazard Analysis and Critical Control Points».

According to the HACCP principle, food companies define critical control points (CCPs) along their internal processes.

A CCP is therefore a step in the production process of a foodstuff at which there is a health hazard that can be prevented by specific control measures.

Each CCP has a limit. If the limit is exceeded, a corrective action must be taken.

The 7 steps of HACCP1 were developed by the National Aeronautics and Space Administration (NASA) in collaboration with the Pillsbury Company in the 1960s to ensure food safety for astronauts during space missions.

7 steps of HACCP

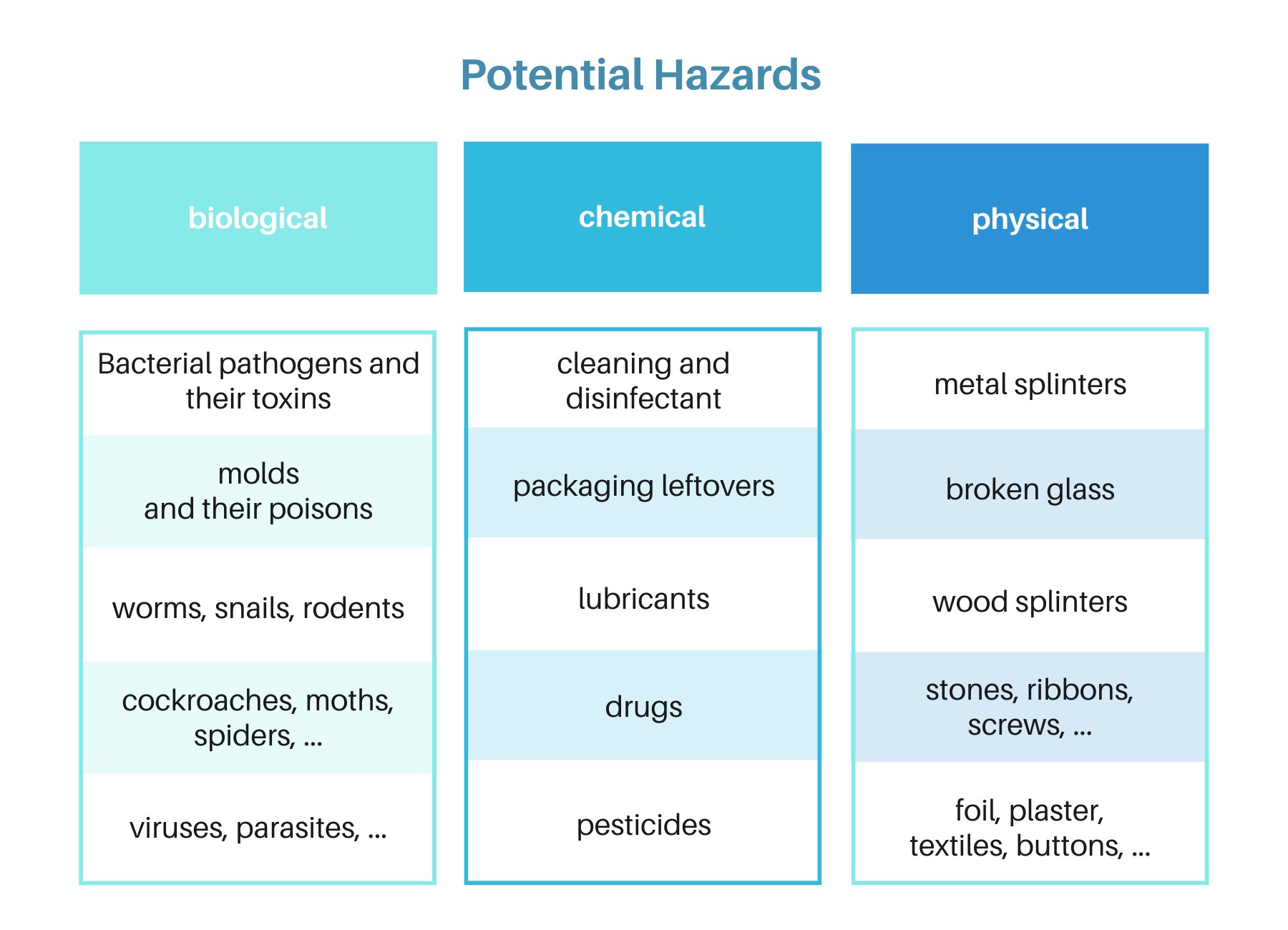

- hazard analysis: identification of potential hazards (e.g. biological, chemical or physical) in the manufacturing process that need to be reduced to an acceptable level, avoided or eliminated.

- identification of critical control points (CCPs) at all stages of the process where monitoring is necessary to prevent, eliminate or reduce a hazard.

- establish critical limits for each control point (CCP).

- establish monitoring measures for each CCP to ensure that the limits are met.

- establishing corrective actions in the event that a limit at a CCP is exceeded or no longer under control.

- establish procedures to verify the effectiveness of the HACCP system (verification), i.e. to check whether the requirements of the HACCP concept are being met or whether improvements need to be made.

- draw up documents and records in accordance with the HACCP concept, depending on the type and size of the operation, in order to be able to prove that the requirements are being met.

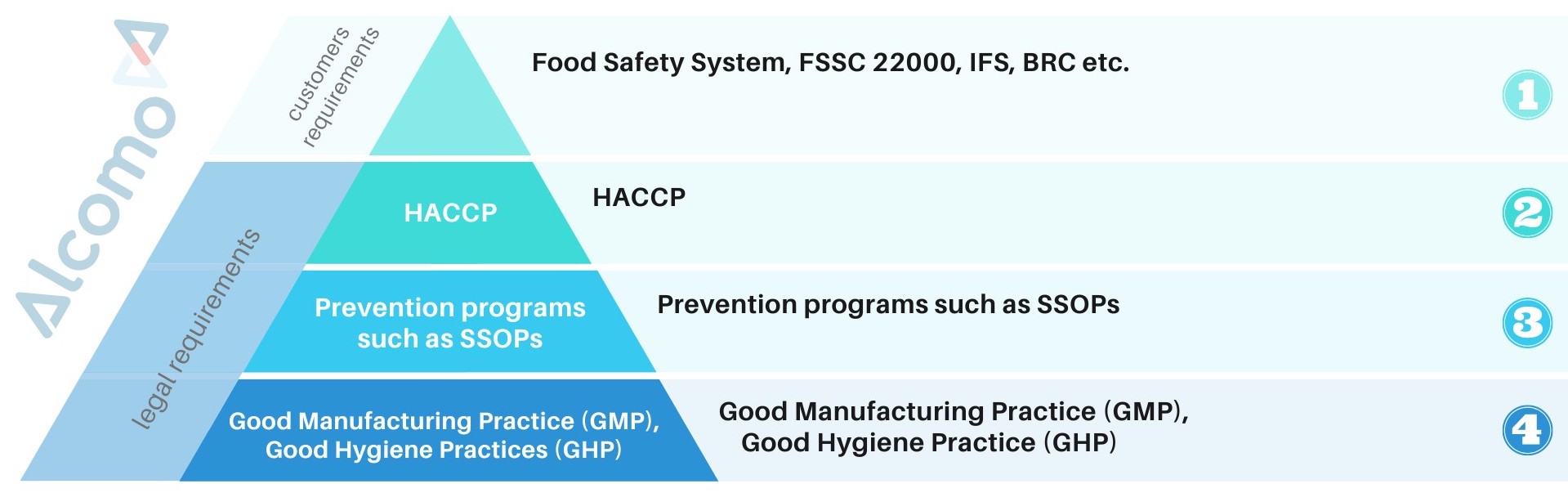

HACCP concept

For a HACCP concept to work, basic prerequisites must be created, which are also called preventive programs. They are considered the foundation of any food safety management system, such as:

- Good Manufacturing Practices (GMP) such as use of approved raw materials, in-process controls, product quality monitoring, etc.

- Good Hygiene Practices (GHP) such as personnel hygiene, hygienic food handling, cleaning and disinfection, etc.

- Prerequisite Programs (PRPs) such as pest control, equipment maintenance, Sanitation Standard Operation Procedures (SSOPs) and cleaning schedules, training, traceability and recall procedures.

In the gastronomy and catering industry, the following processes are usually monitored as part of the HACCP concept:

- Goods receiving

- Temperatures of chiller and freezer

- Heating temperatures

- Cooling temperatures (quick chilling)

- Food temperatures during processing (cooling chain interruption)

- Food temperatures at food servery (hot holding, cold holding)

- Food temperatures during delivery service

- Frying oil checks

- …

In the gastronomy and catering industry, the following processes are usually monitored as part of the preventive programs and good hygiene and manufacturing practice:

- Cleaning and disinfection (cleaning schedule, cleaning checklists).

- Pest control

- Equipment maintenance

- Retention samples

- Monitoring of storage (use-by and best-before dates of food)

- Training (hygiene, HACCP, infection control, cleaning and disinfection, food handling, etc.)

- Staff hygiene (hand washing, work clothes, etc.)

- …

Food Safety Management Systems (FSMS)

Food Safety Management Systems (FSMS) have a structure that contains the following elements:

- SOPs (Standard Operating Procedures)

- WIs (Working Instructions)

- Records – verification documents and checklists